Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

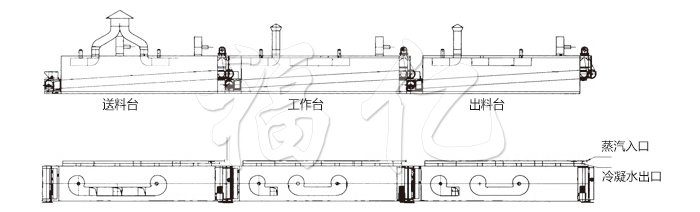

Working principle

Dehydrated vegetables dryer were feeder, drying bed, heat exchanger and fan and other major components. When the dryer works, the cold air is heated by a heat exchanger. A scientific and rational cycle method is adopted to make the hot air flow through the drying material on the bed surface to carry out the uniform heat and mass exchange, the air flow in each unit of the unit carries out hot air circulation under the action of the circulation fan. Finally, exhaust the air with low temperature and high humidity, and complete the drying process smoothly and efficiently.

Product introduction

DWC dewatering dryer is a kind of special equipment developed on the basis of traditional belt dryer. It has strong pertinence, practicability and high energy efficiency. Widely used in various types of seasonal and seasonal vegetables, fruits dehydration drying. Such as: garlic slices, pumpkin, konjac, white radish, yams, bamboo shoots and so on. When we are producing equipment for the user, according to the characteristics of drying products, the user process requirements, combined with decades of accumulated experience, for users to design and produce the most suitable and best quality vegetable drying equipment.

Adaptive material

The utility model can satisfy the drying and mass continuous production of vegetable materials such as roots, stems, leaves, strips, blocks, sheets, large granules, etc., and meanwhile, the nutrition contents and colors of the products can be retained at the most.

The typical drying materials are garlic slices, pumpkin, carrots, konjac, yams, bamboo shoots, horseradish, onions, apples and so on.

Performance characteristics

The drying area, air pressure, air volume, drying temperature and belt speed can be adjusted to meet the requirements of vegetable characteristics and quality.

According to the characteristics of vegetables, adopt different technological processes and add necessary auxiliary equipment.

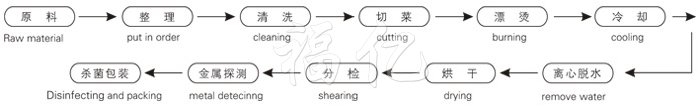

Technological process

Technical specifications

|

Model |

DWC1.6-Ⅰ |

DWC1.6-Ⅱ |

DWC1.6-Ⅲ |

DWC2-Ⅰ |

DWC2-Ⅱ |

DWC2-Ⅲ |

|

Net width belt(m) |

1.6 |

1.6 |

1.6 |

2 |

2 |

2 |

|

Drying section length(m) |

10 |

10 |

8 |

10 |

10 |

8 |

|

Paving thickness(mm) |

≤100 |

≤100 |

≤100 |

≤100 |

≤100 |

≤100 |

|

Service temperature(℃) |

50-150 |

50-150 |

50-150 |

50-150 |

50-150 |

50-150 |

|

Heat exchange area (m2) |

525 |

398 |

262.5 |

656 |

497 |

327.5 |

|

Vapour pressure (Mpa) |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

0.2-0.8 |

|

Drying time (h) |

0.2-1.2 |

0.2-1.2 |

0.2-1.2 |

0.2-1.2 |

0.2-1.2 |

0.2-1.2 |

|

Transmission power(kw) |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

|

Outline size(m) |

12×1.81×1.9 |

12×1.81×1.9 |

12×1.81×1.9 |

12×2.4×1.92 |

12×2.4×1.92 |

10×2.4×1.92 |